Open bearing – Air Circulation

In this configuration an air passage is provided to the bearing area. The compressed air cools and lubricates the bearings and blows away any drilling debris extending the life of the bearing. This bearing configuration is commonly used in Blasthole Mining applications

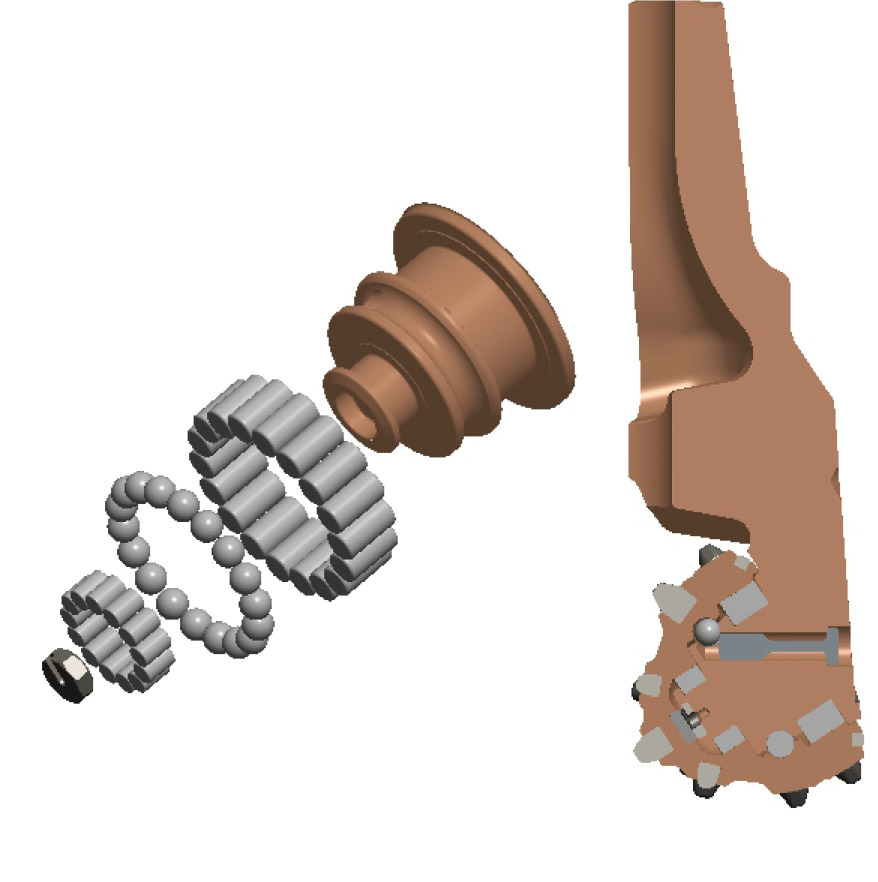

Open bearing - Air, Mud or Foam Circulation

The standard open roller bearings are without a seal or an air passage. They are ideal for drilling shallow holes, in the hundreds of feet with either foam or mud circulation. These bearing configurations are commonly used in Water Well applications.

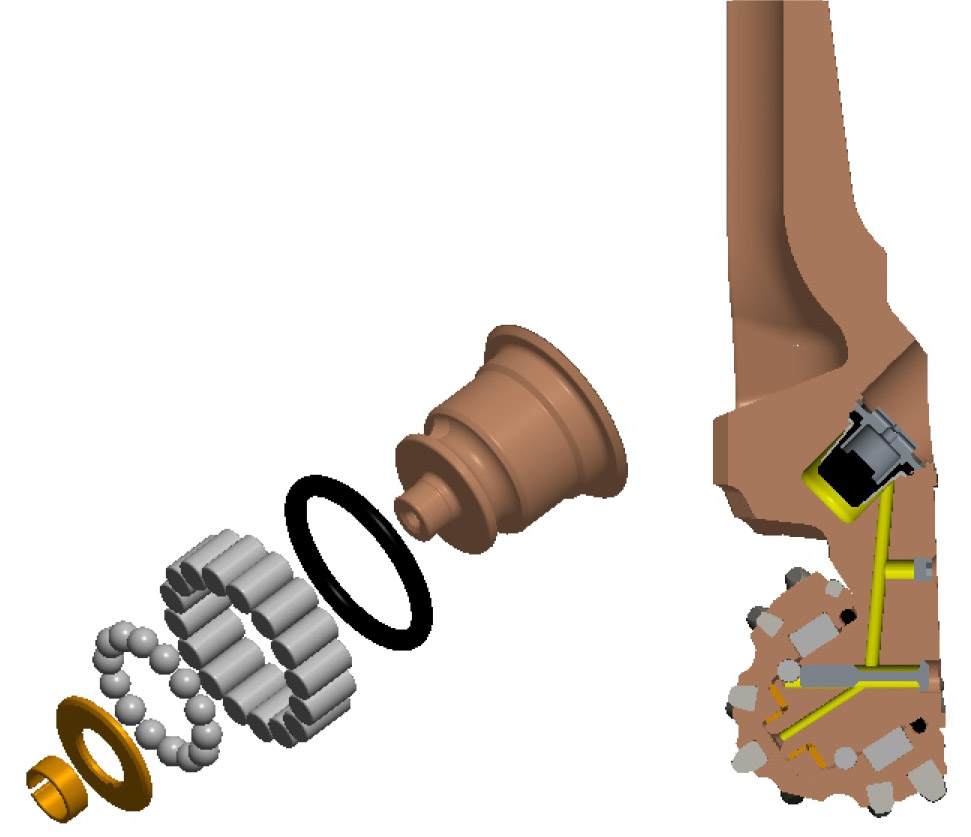

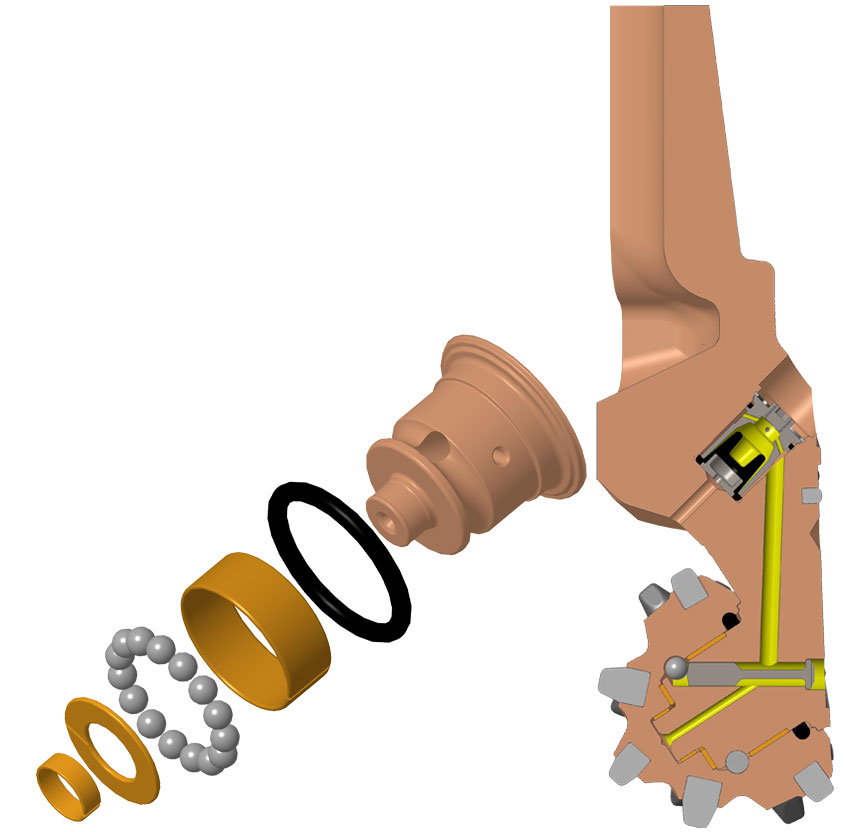

Semi-Sealed bearing – Air Circulation

Semi-Sealed bearings for air circulation are similar to Open Air bearings, only difference being the bearing pack protected with an O- Ring Seal. The lubricant is filled into the bearing and sealed off. This prevents ingress of dirt into the bearing system and leakage of grease. This configuration is used for Mining applications with heavy water injection and ground water conditions

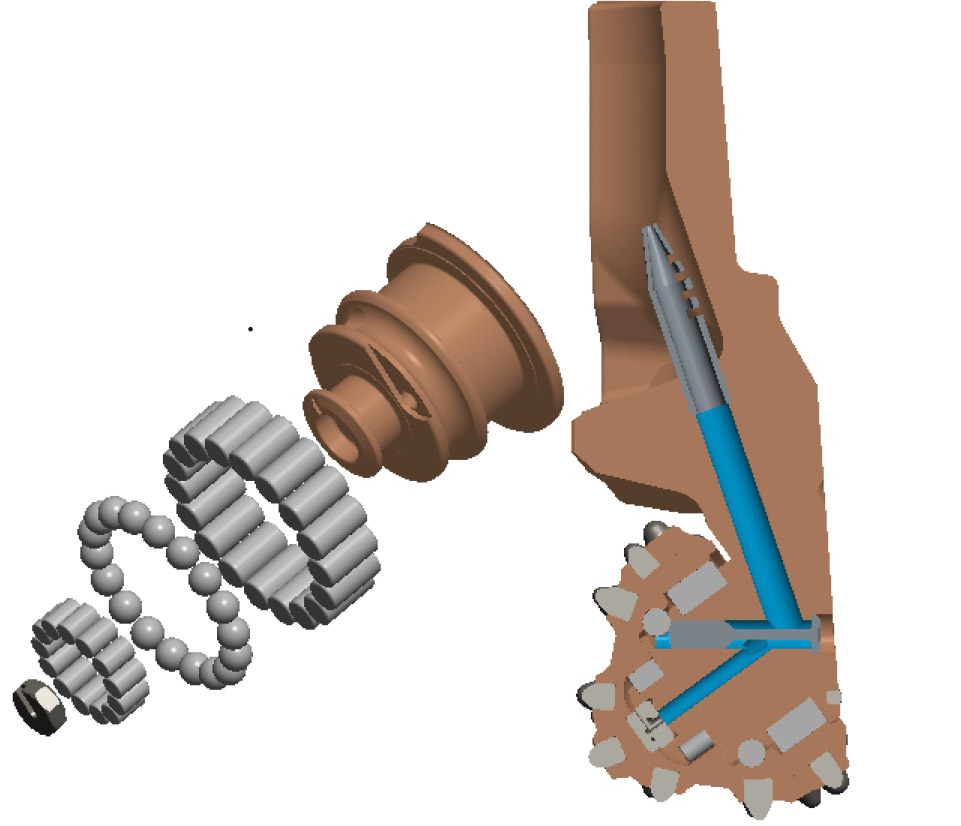

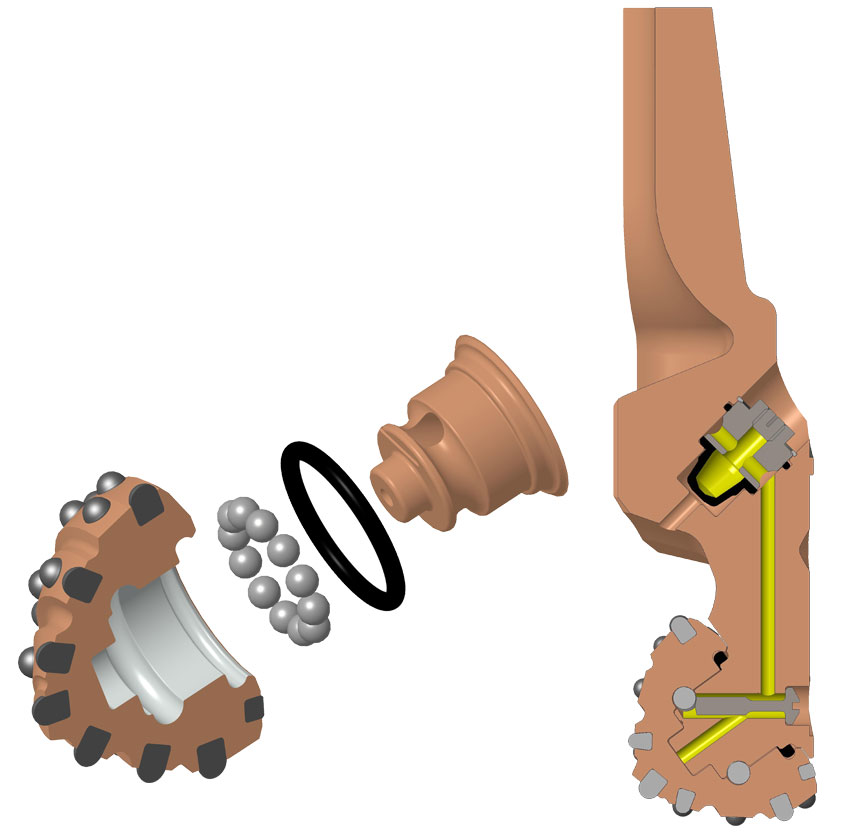

Sealed Journal bearing - Air & Mud circulation

In Sealed Journal bearing the Rollers inside the cone are replaced by a Floating Bush made out of special alloys which is silver plated. The bearing Pack is protected with an O-Ring Seal. The bearing lubrication and pressure compensator system is built in. The Floating Bush is highly resistant to heat and galling. Consequently these bearings are very durable and suitable for Mining, Raise Boring, HDD applications

Sealed friction bearing - Mud circulation

In bearings for Small Diameter Bits instead of the Floating Bush the internal surface of the Cone is silver plated using a special process. This design enables bearing size to be increased in relation to the diameter of the Bit enhancing its durability. This bearing design finds application in Reverse circulation and Waterwell drilling applications

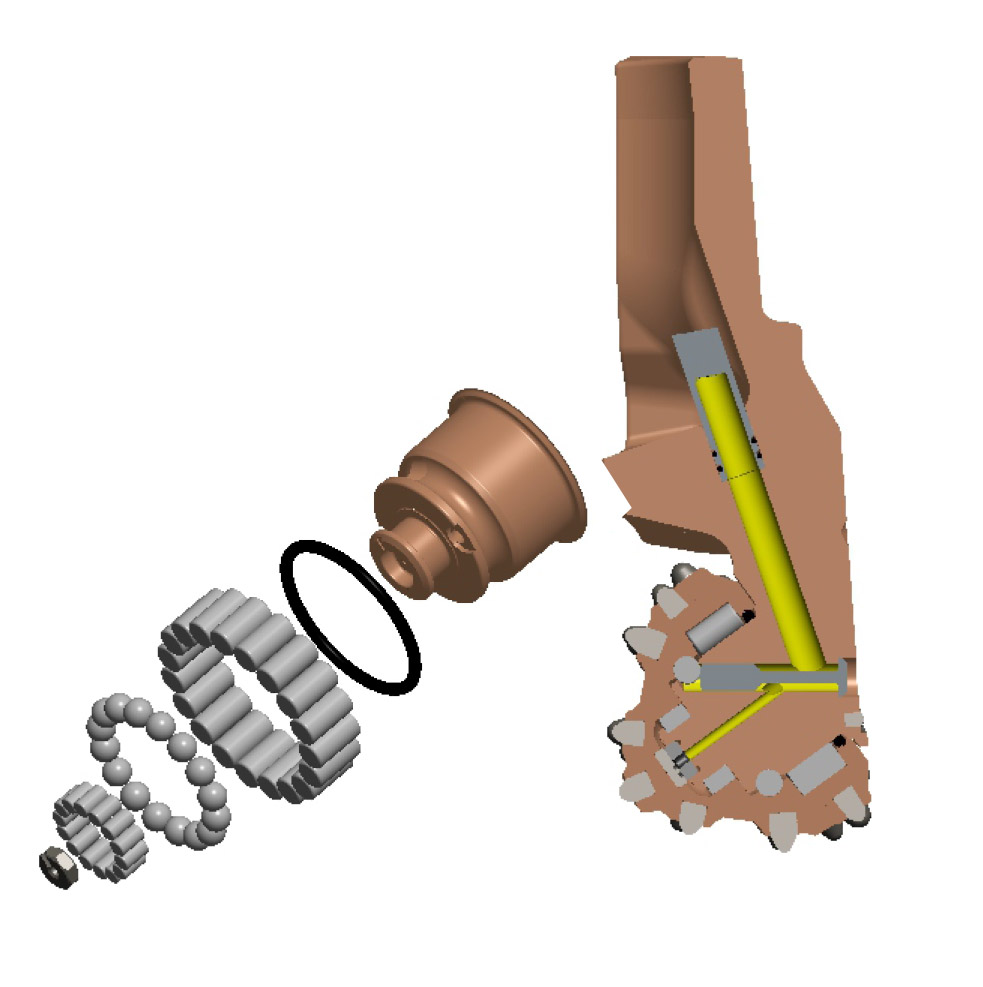

Sealed roller bearing – Air & Mud Circulation

While sealed roller bearings have some of the features of Open to Air bearings, the bearing pack is protected with an O- Ring Seal and has lubrication and pressure compensator system built in. This prevents ingress of dirt into the bearing system and leakage of grease. This configuration is used for Mining, Exploration applications